For Accurately Engineered Results, Use a Precision Linear Motors Stage Device

Moment, there is numerous diligence that depends on direct stage bias for a wide range of programs and artificial operations. This is a device that offers unequaled delicacy and convenience when it comes to operations belonging to nano-positioning and micro-positioning fields.

The Principle of Work

All products are constructed slightly. They correspond to two effects-a base and a platform. The corridor of the direct stage that includes a base and a platform is linked by direct bearing or companion in such a way that the platform is confined to any type of direct stir about the base. It's always the platform the device that moves about its base.

The Precision Linear Motors stage only exhibits one degree of freedom, i.e., the stir in the system is confined to only one axis by the system companion. The system allows for effective stir restatement along any one axis in the overall three-dimensional space. Whether it's the X-axis, Y-axis, or the perpendicular Z-axis, the stir is performed in any one restatement axis.

Utmost of the time, the sliding stir created in the system has been interchangeably appertained to as a direct slide. Still, in specialized parlance, the direct slide is only an element of a direct stage and is generally appertained to a direct stir bearing. This device is an atomic part of a large stir control system or is generally also addressed as a small element that constitutes a part of a direct-moving stage. Its main part is to perform the task of constricting a specific section of the system to one single stir axis.

Operations

Moment, with adding technologies and inventions in every field, there are hundreds to thousands of artificial operations that bear motorized perfection direct stage and perfection control bias for fulfilling manifold artificial and marketable requirements. Thus, these biases are substantially planted in fields similar as metrology, microscopy, ray, scanning, examination, water scribing, biotechnology, and numerous further.

Utmost of the time, these stages are employed in operations that amount to high speed, delicacy, acceleration, and repeated use over expansive work hours. Nevertheless, many features determine that a direct stage device is truly a state-of-the-art machine. So let us see below some of the most defining factors for the same.

True Factors that Define the Performance of a Linear Stage

- The stage should offer precise line control.

- It should give superior delicacy, performance, and repetition.

- The stages are grounded on the stepper or servo motors along with direct comportments. Hence, all these factors must serve easily and faultlessly.

- For super-complex operations, some manufacturers also offer direct stages in sub-micron perfection.

- In addition, the most pivotal factor to consider is the quantum of disunion the device creates in the stage when it's put to use.

When you plan to invest in a perfect direct stage device, the most important maybe, the foremost factor you must decide upon is the distance you want to cover up or want the stage to travel during the operation. Grounded on this note, a sprinkle of factors similar as delicacy, perfection, minimal rise in stir, and repetition are inversely determined.

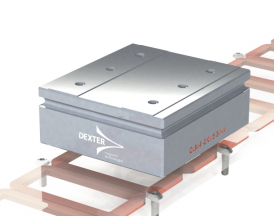

Dexter Magnetic Technologies has always fascinated the technician inside me. And writing about the rearmost in technologies and mechanisms in operation has been my specialty over the last many times. Follow my write-ups to know about the rearmost in technologies and mechanisms this season for one. This fall perfection stir control, linear motor, perfection direct stage are veritably much in demand among the specialized and mechanical diligence across the world.

Our Source:-https://sites.google.com/view/precision-linear-motors/home

Comments

Post a Comment